CENTRE DE PRODUITS

Is a new kind of high-tech-based environmentally-friendly flooring featuring zero formaldehyde, mildew proof, moisture proof, fire proof, insect proof, and simple installation.

WHY CHOOSE BAOSHANG

Is a new kind of high-tech-based environmentally-friendly flooring featuring zero formaldehyde, mildew proof, moisture proof, fire proof, insect proof, and simple installation.

VERT

The main raw material for the production of stone plastic flooring is natural stone powder, which is detected by the national authority without any radioactive elements, and is a new type of green and environmentally friendly ground decoration material

SUPER LIGHT AND THIN

Stone plastic floor is only 4-6mm thick and weighs only 10-12KG per square meter, which is less than 30% of ordinary ground materials.

SUPER WEAR RESISTANCE

Stone plastic floor surface has a special layer of high-tech processing of the transparent wear-resistant layer, the wear-resistant revolution of up to 300000 rpm

HIGH FLEXIBILITY

Stone plastic floor texture is soft, so the elasticity is very good, in the impact of heavy objects has a good elastic recovery, its foot comfort is called "soft gold floor material"

FIREPROOF AND WATERPROOF

The raw materials of stone plastic floor are stone powder and PVC powder. The two raw materials themselves are waterproof and fireproof, so stone plastic floor is also waterproof and fireproof.

NEWS CENTER

Is a new kind of high-tech-based environmentally-friendly flooring featuring zero formaldehyde, mildew proof, moisture proof, fire proof, insect proof, and simple installation.

Congratulations on the official launch of the website of Chiping Baoshang Plastic!

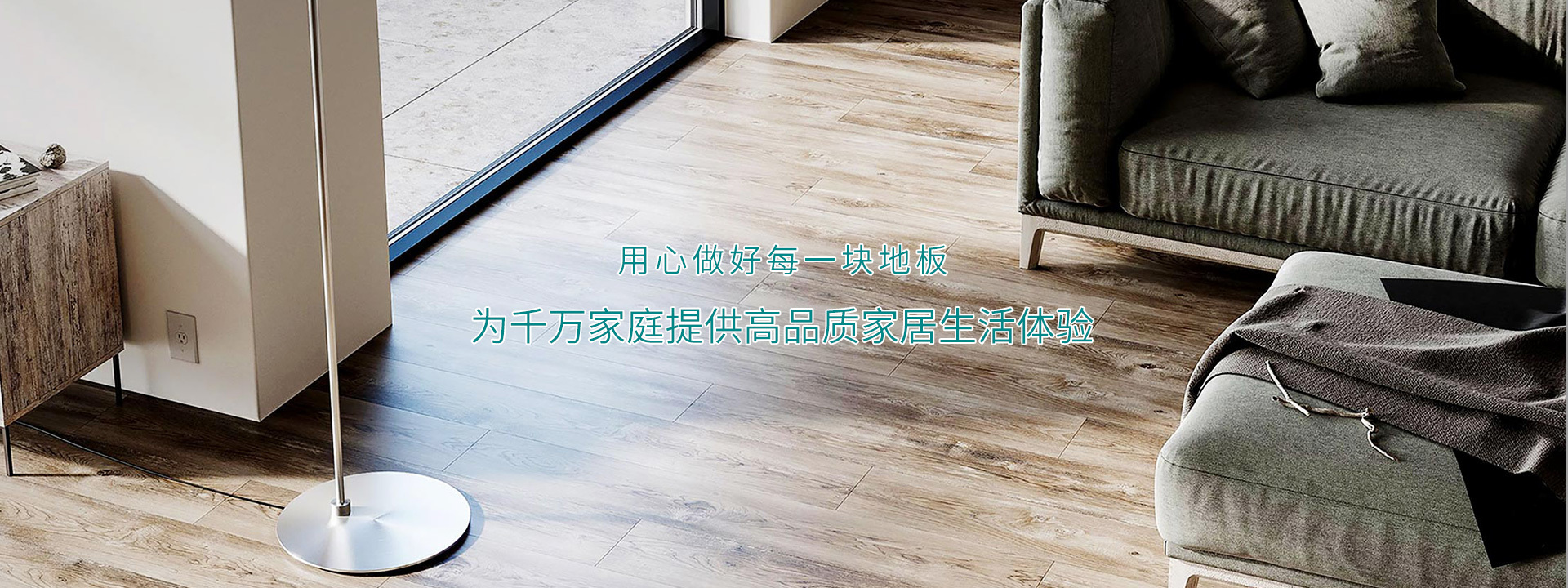

CHIPING BAOSHANG PLASTICS CO., LTD.

SPC(stone plastic compostic) stone plastic floor is a new type of environmentally friendly floor developed based on high technology. It has the characteristics of zero formaldehyde, mildew resistance, moisture resistance, fire resistance, insect resistance, and simple installation. SPC floor is a PVC substrate extruded by an extruder combined with a T-die, and PVC wear-resistant layer, PVC color film and PVC substrate are respectively heated and laminated by a three-roll or four-roll calender. The product process of embossing is simple, and the bonding is completed by heat without glue.